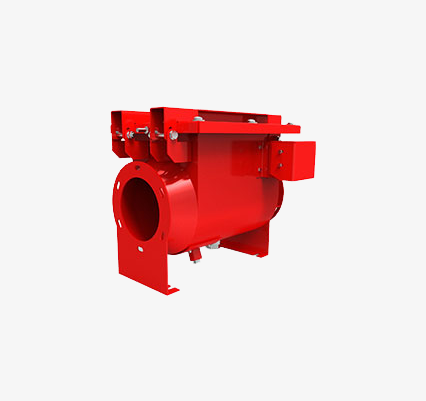

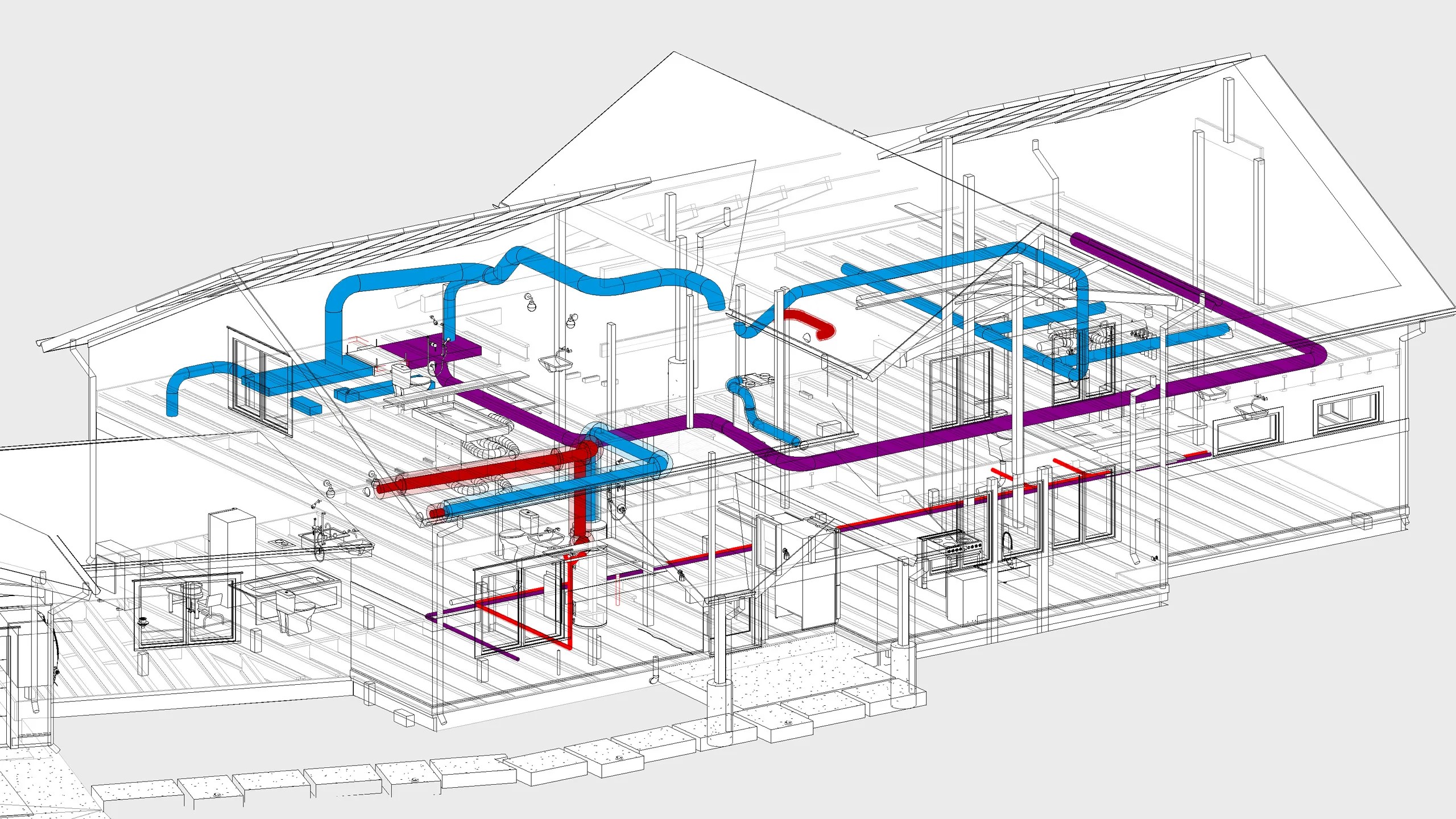

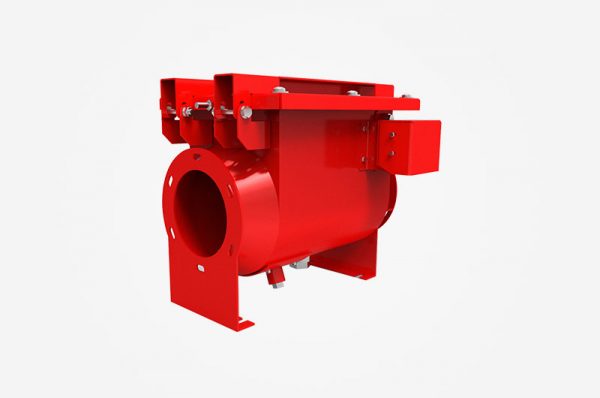

The non return isolation valve is normally installed on the inlet pipeline of a dust collector or a cyclone separator. It is a simple, economical and reliable isolation product. It is mainly used to prevent the flame and shock waves inside the device which are generated from explosion from spreading to upstream pipeline and devices.

Product Details

A passive gravity type dust explosion isolation valve, not trigger by a sensor, available in normal open and normal close types;

Applicable to non return isolation, negative pressure system and horizontal installation;

Applicable dusts: organic dust and inorganic dust (containing metal dust);

Sizes available from DN100 to DN1000;

Material: Shell, Q235 (carbon steel) with RAL 3000 (coating color), Flap: 304SS (stainless steel);

Applicable wind speed: 15-30m/s;

Pressure loss: about 200 pa;

Max reduced explosion overpressure (Pred, max): 0.7 barg@20℃;

Applicable dusts: St1 and St2 dusts with Kst less than and equal to 300barg*m/s;

Installation method: horizontal installation, connected by flanges;

Installation position: 3-7m from the pipeline of dust collector inlet;

Operation conditions monitored via an integrated sensor, thus allowing longer maintenance intervals;

Solid and durable design, requiring minimal maintenance;

Coming with a inspection cover, easy for inspection;

Signal sensors and closed position indicator switches and other accessories optional;

Testing reports from domestic authorities are available;

-

Address:Dafeng, Yancheng, Jiangsu, China 224100

-

Tel: 86-515-83285388

-

Phone: 86-13337983999

-

Fax: 86-515-83285377

-

Email: David.Wei@DragonIndustries.com

Copyright © Dragon Industries Copyright Reseved 丨苏ICP备11020828号-9 苏

Copyright © Dragon Industries Copyright Reseved